ITEM |

SPECIFICATION |

YLM-10A |

Capacity |

Swing over bed |

∮700mm(∮27.6") |

Swing over cross slide |

∮495mm(∮19.5") |

|

Std. turning dia. |

∮495mm(∮19.5") |

|

Max turning dia. |

∮520mm(∮20.5") |

|

Max turning length |

586mm(23") |

|

Distance between center |

710mm(28") |

|

Travel |

X axis |

260(235+25)mm/10.2" |

Z axis |

586mm(23") |

|

Guide way |

Linear Guides |

|

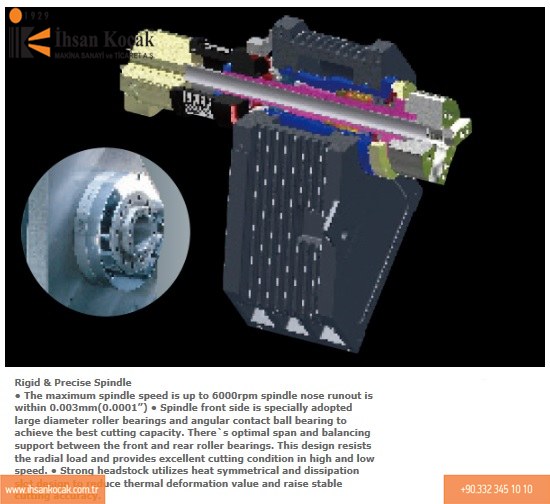

Spindle |

Spindle nose |

A2-8 |

Spindle bearing dia. |

∮130mm(∮5.1") |

|

Max spindle speed |

3500rpm |

|

Spindle bore |

90mm(3.5") |

|

Draw tube bore |

75mm(3") |

|

Chuck size |

10 inch / 3-Jaw |

|

C-axis min. index angle |

- |

|

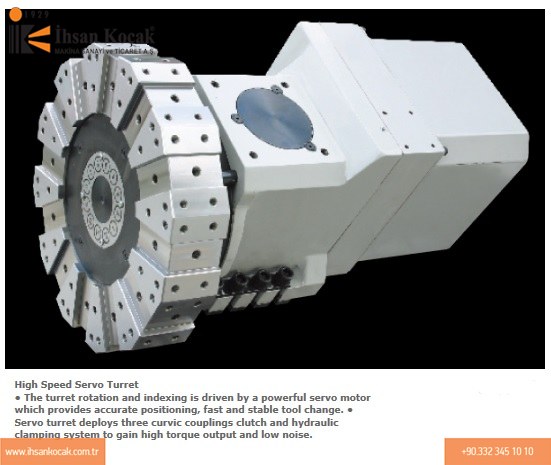

Turret |

Turret type |

mm/inch |

Driven way |

servo motor |

|

No. of tools |

12 |

|

Tool shank size |

□25mm(□0.98") |

|

Max. boring bar dia. |

∮40mm((∮1.6") |

|

Power turret |

Turret type |

- |

Driven way |

- |

|

No. of tools |

- |

|

Tool holder spec.(NON-Live) |

- |

|

Tool holder spec.(Live) |

- |

|

Tool shank size / boring bar dia. |

- |

|

Live tooling collet spec./ size |

- |

|

Max. live tooling speed |

- |

|

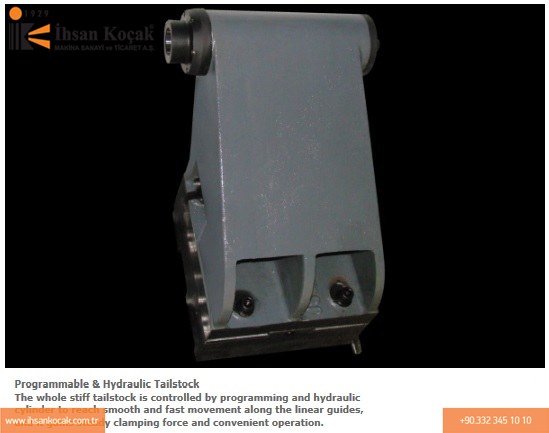

Tailstock |

Driven way |

Programmable hydraulic |

Center MT# |

MT#5 |

|

Travel |

680mm(26.7") |

|

Feedrate |

X/Z axis rapid feedrate |

30m/min.(1181ipm) |

Cutting feedrate |

1260mm/min.(49.6ipm) |

|

Servo Motor |

Spindle motor |

15 / 18.5 kW(P-type) |

Spindle speed (full power output) |

233rpm |

|

Axis motor |

15 / 18.5 kW |

|

Servo motor |

850 W(1.1hp) |

|

Power turret motor |

- |

|

CNC Controller |

|

FANUC 0iTD |

Motor |

Chip conveyor motor |

188 W(0.25hp) |

coolant pump motor |

700 W(0.93hp) |

|

hydraulic pump motor |

1510 W(2hp) |

|

Dimension |

Floor space |

2950x1850x2000mm |

Net weight |

4650kg(10230lbs) |

Standard accessories |

|||

1. |

FANUC 0iTD controller |

9. |

Auto.lubrication system |

2. |

3-jaw hydraulic chuck |

10. |

Tool kit |

|

●Soft jaw one set |

11. |

Leveling bolt and pad |

|

●Hard jaw one set |

12. |

Cutting Tool holder(12T) |

3. |

Servo turret (cap. 12T) |

|

●2 pcs(YLM-8B&10A) |

4. |

Full enclosed splash gurad |

13. |

Boring Bar holder |

5. |

Working light |

|

●6 pcs(YLM-8B&10A) |

6. |

Warning light |

14. |

Boring Bar Bushing 1 set |

7. |

Hydraulic system |

15. |

Driller Bushing 1 set |

8. |

Coolant system |

|

|

Optional accessories |

|||

1. |

Collet chuck & collets |

11. |

Live center |

2. |

Auto Tool length measurement |

12. |

Air conditioner(electrical) |

3. |

Parts catcher (belt conveyor) |

13. |

VDI power turret |

4. |

Bar feeder |

14. |

C axis (0.001°) |

5. |

Programmable hydraulic tailstock |

15. |

VDI axial tool holder(non-live) |

6. |

Chain type Chip conveyor with chip cart |

16. |

VDI radial tool holder(non-live) |

7. |

Auto. Door |

17. |

VDI axial mill tool holder (power) |

8. |

Oil mist collector |

18. |

VDI radial mill tool holder (power) |

9. |

Oil skimmer |

|

|

10. |

Gantry robot |

|

|